Our engineering team created this new patent pending 3 pocket design specifically for demanding turbocharged supercharged and big nitrous applications.

Best connecting rods for nitrous.

For limited induction engines the rod should be as long as possible.

This allows the thickness and cross sectional area of the rod to be reduced so the rod can be 10 to 20 lighter than a comparable rod made of 4340 steel.

This alloy has a higher level of silicon 1 45 to 1 80 and a little more carbon and molybdenum for added strength.

I will shed a little light on selecting the length of your connecting rods but this is a whole article in itself.

Steel rods can become prohibitively heavy in large displacement long stroke engines.

Most aftermarket steel connecting rods are made from forged steel.

Nitrous can bend connecting rods if triggered at too low an rpm especially if the car is in high gear since the additional power is more than the internal components can handle.

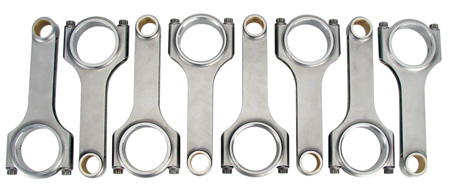

Introducing boostline connecting rods.

There are some practical considerations when choosing a connecting rod.

For example cast steel connecting rods were used in many 1960s and 70s vehicles but they are not great for any type of performance applications.

And the best.

We have never had a rod failure when using these rods.

Many rod suppliers are making steel connecting rods out of 300m alloy.

Steel connecting rods are made with various types of materials and manufacturing processes.

These connecting rods are ideal for today s high horsepower engines and provide 60 more bending strength compared to common h beam rods.